The Benefits of Bespoke Silicone Hose

Silicone may not be the obvious choice for hose assemblies due to its apparently high cost. But bespoke silicone hose can actually reduce costs compared to the time consuming black rubber assemblies. Silflex has over 20 years of experience in designing such hose solutions, which not only saves time and assembly costs but also component costs. Joiners and clips become unnecessary and this also has the added advantage of improving flow and reducing leak paths. Silicone also offers better performance at low and high temperatures.

Case Study:

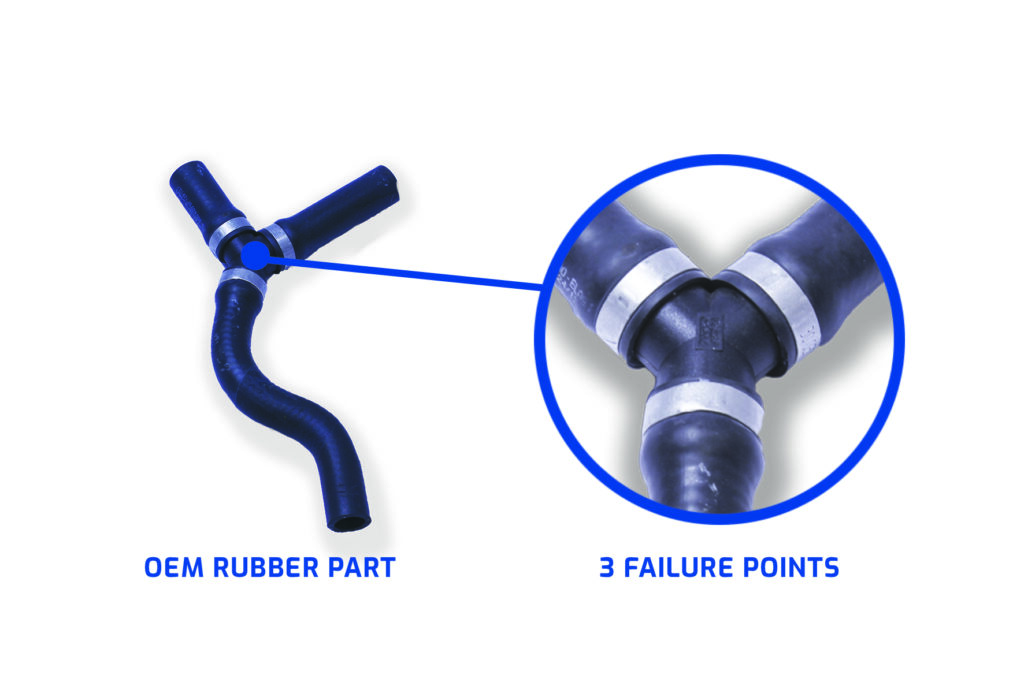

On a visit to an OEM customer who manufactures specialist vehicles, we looked and the awkward assembly they were using on their intake system. We were able to replace this with a custom-designed silicone hose that saves them a considerable amount of time and money. We were able to vastly improve the design and shape, as well as repositioning the two small take-off branches to a much better position which they were unable to achieve with their existing assemblies.

Silflex Silicone Hose:

- Save on component cost

- Save on assembly time

- Improve flow

- Reduces leak possibilities

- Incorporate alloy / Stainless Steel inserts

- Improve aesthetic appearance

- Offer temperatures between -50°C to 250°C

- Rapid prototype development

- Low tooling costs